Overview

Current lead time is 6 weeks

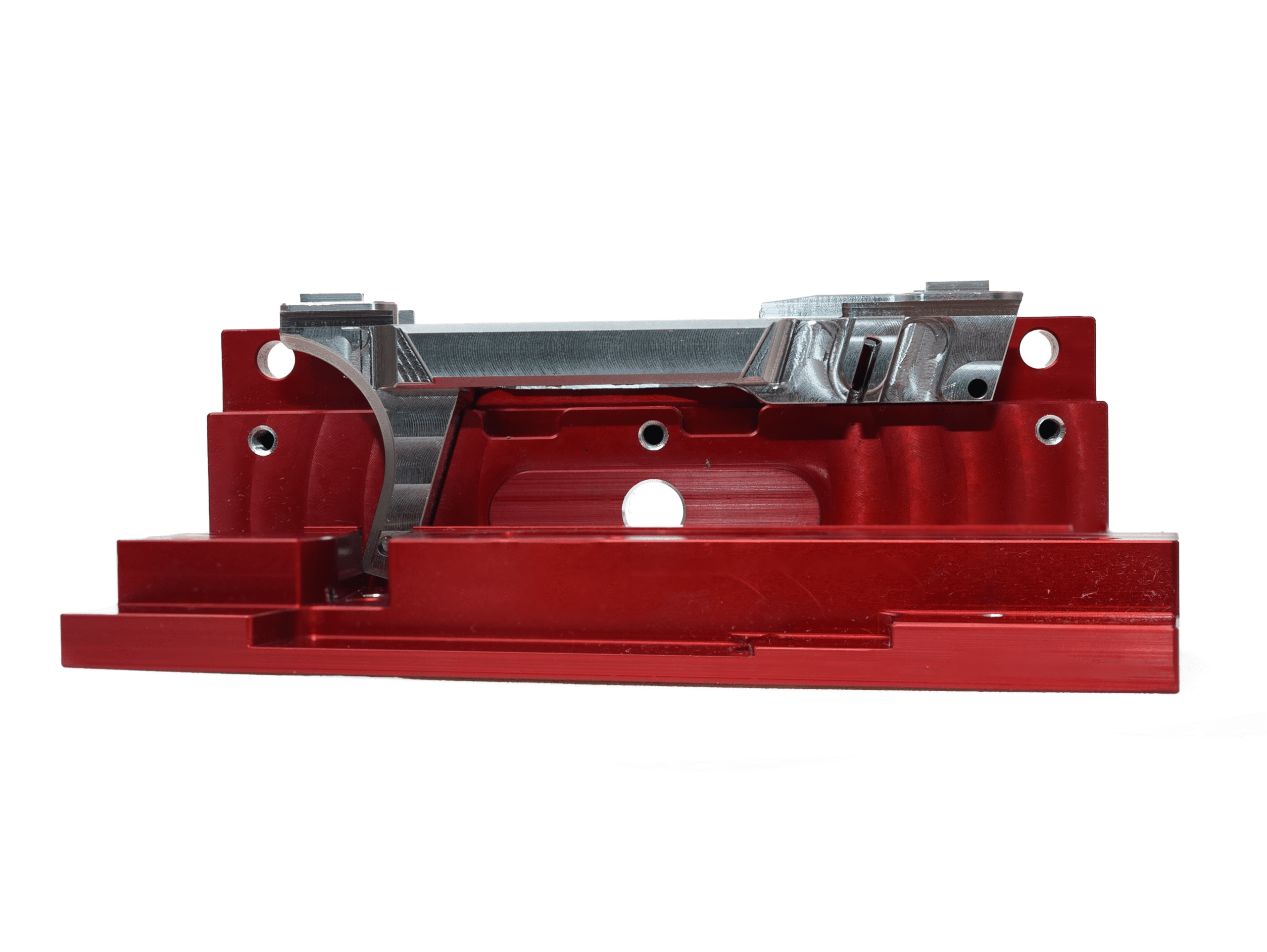

The G80 Jig is the precision tool you need to finish your G80 unfinished receiver with confidence. Unlike universal jigs that require constant adjustments and workarounds, this jig is engineered specifically for the G80 platform.

No modifications, no adapters, just a perfect drop-in fit that works right out of the box.

Whether you’re old school with a dremmal or running a GG3-S machine, this jig adapts to your workflow. The intuitive design and minimal components mean you’ll spend less time figuring things out and more time actually building.

Built from rugged materials that hold their accuracy through build after build, this isn’t some one and done disposable jig. The precision machined construction eliminates the walk, chatter, and misalignment issues that plague cheaper jigs, giving you clean, professional cuts every time.

Features

No mods, no adapters. just a clean drop-in fit

Whether you prefer hands-on or automated, the jig supports both workflows

Built tough to withstand repeated use without losing accuracy

Reduces walk, misalignment, and chatter for tight, consistent results

Minimal components and intuitive layout for fast and frustration-free finishing

In the Box

- 1x G80 Jig Hardware Set

- 2x 3.1mm Drill bit

- 1x 4.1mm Drill bit

- 1x Grinding Stone – Large

G80 Jig FAQ

The G80 Jig supports both manual and machine finishing methods. For manual builds, you’ll need a Dremel rotary tool (we recommend cutters SKU 85602 and 85422) along with the included drill bits and grinding stone. For machine finishing, the jig is fully compatible with the GG3-S automated system. Unlike generic 80% kits that require adapters or modifications, the G80 Jig is purpose-built for the G80 unfinished receiver. Just drop it in and start working.

The G80 Jig is built for repeated use. While many disposable jigs included with cheaper 80 percent pistol kits lose accuracy after a single build, ours is precision-machined from rugged materials designed to maintain tolerances across multiple builds. If you’re planning to finish more than one G80 unfinished receiver, or help friends complete their 80 percent build kits, this jig pays for itself.

Most builders can finish their G80 unfinished receiver in 1-2 hours using manual tools. Machine finishing with a GG3-S is faster. The intuitive design and minimal components mean less time troubleshooting and more time actually building. This completion time also keeps the G80 system compliant with federal guidelines established in the VanDerStok decision.

No. The G80 Jig is engineered exclusively for the G80 unfinished receiver, a heat-treated billet steel FCU rather than a polymer frame. This purpose-built design eliminates the fit issues, walk, and misalignment problems common with universal jigs. If you’re building a G80, this is the only jig you need.

Everything you need comes in the box: the G80 Jig hardware set, two 3.1mm drill bits, one 4.1mm drill bit, and a large grinding stone. No hunting down third-party bits or adapters. The included drill bits are specifically sized for the G80’s pin holes, ensuring proper alignment when you install your Glock Gen 3 compatible parts kit.

Three key differences: First, the G80 Jig is designed for a steel unfinished receiver, not polymer, resulting in a more durable finished firearm. Second, it’s built for repeated use rather than being disposable. Third, it requires no modifications or adapters. The drop-in fit eliminates the guesswork that causes build failures with generic 80 kits.

The G80 system was designed to comply with federal law as interpreted by the Supreme Court in the VanDerStok decision. The majority ruled that kits shipped without every necessary component, requiring uncommon tools and over an hour to complete, are not subject to the ATF’s 2022 receiver rule. However, some states have banned privately made firearms (PMFs), and G80 does not ship to those restricted states. Always verify your local laws before purchasing any 80 percent kit.

Yes. Many builders use a drill press with a 1/4″ end mill to peck-drill the metal obstructions in the unfinished receiver. The G80 Jig’s precision machining ensures consistent results whether you’re using a drill press, Dremel tool, or automated GG3-S machine. Choose whichever method matches your workshop setup and skill level.

Once you’ve finished your G80 unfinished receiver using the jig, it accepts any OEM or aftermarket Glock G19, G23, or G32 Gen 3 components, including complete slides, frame parts kits, and Gen 3-5 magazines. The G80 receiver is also 120R-compatible and works with any 120R grip module. Note: the G80 system includes its own pins and coiled spring that substitute for certain parts in standard Glock lower parts kits.

You’re not paying for a disposable piece of plastic. You’re investing in a precision tool. The G80 Jig is machined to tight tolerances that prevent the walk, chatter, and misalignment that ruin builds. It’s designed for repeated use across multiple G80 unfinished receivers, making it more economical per-build than single-use alternatives. For serious builders, quality tooling isn’t an expense. It’s the foundation of a reliable 80 percent firearm.