Overview

Current lead time is 4-6 weeks

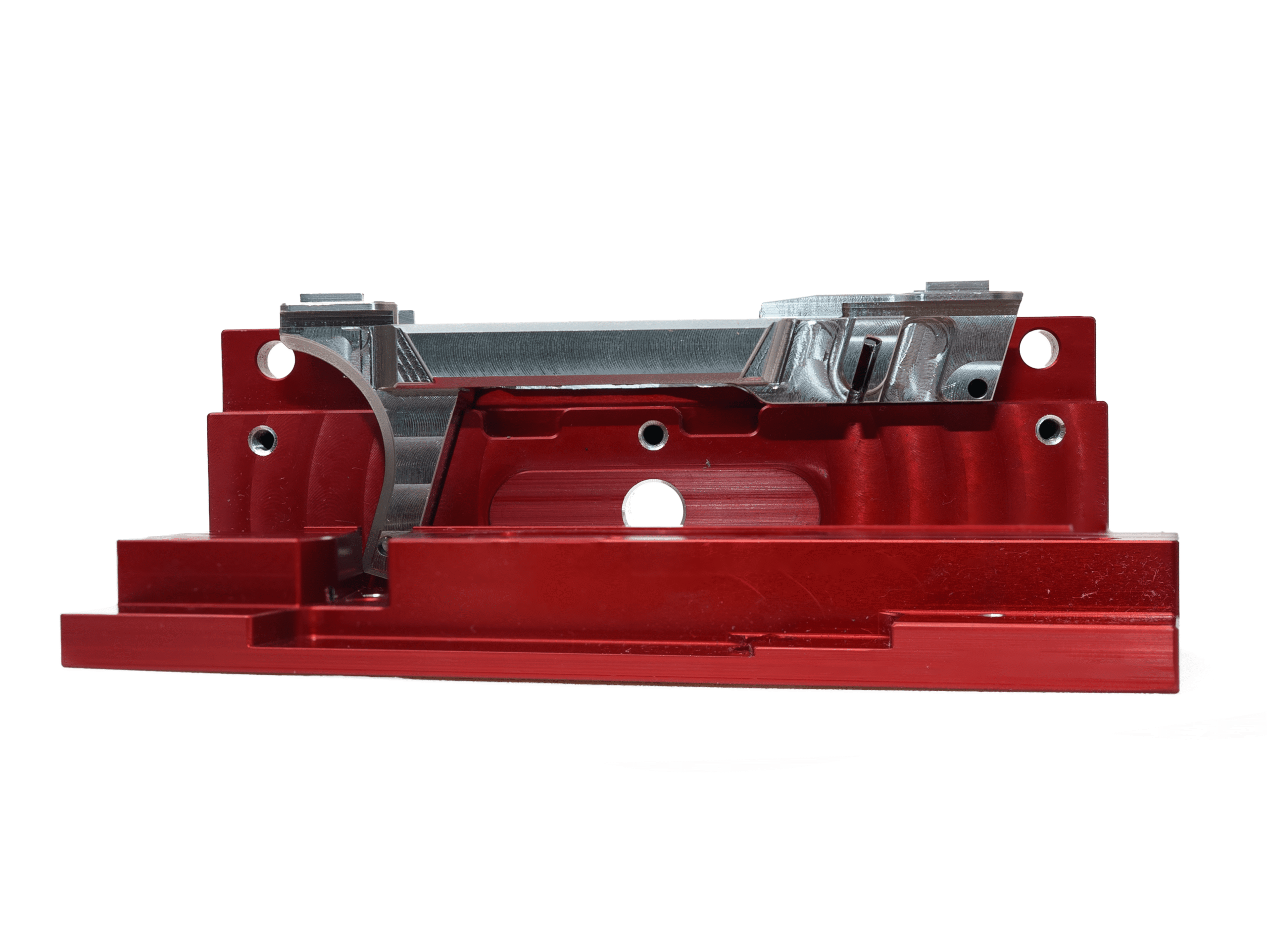

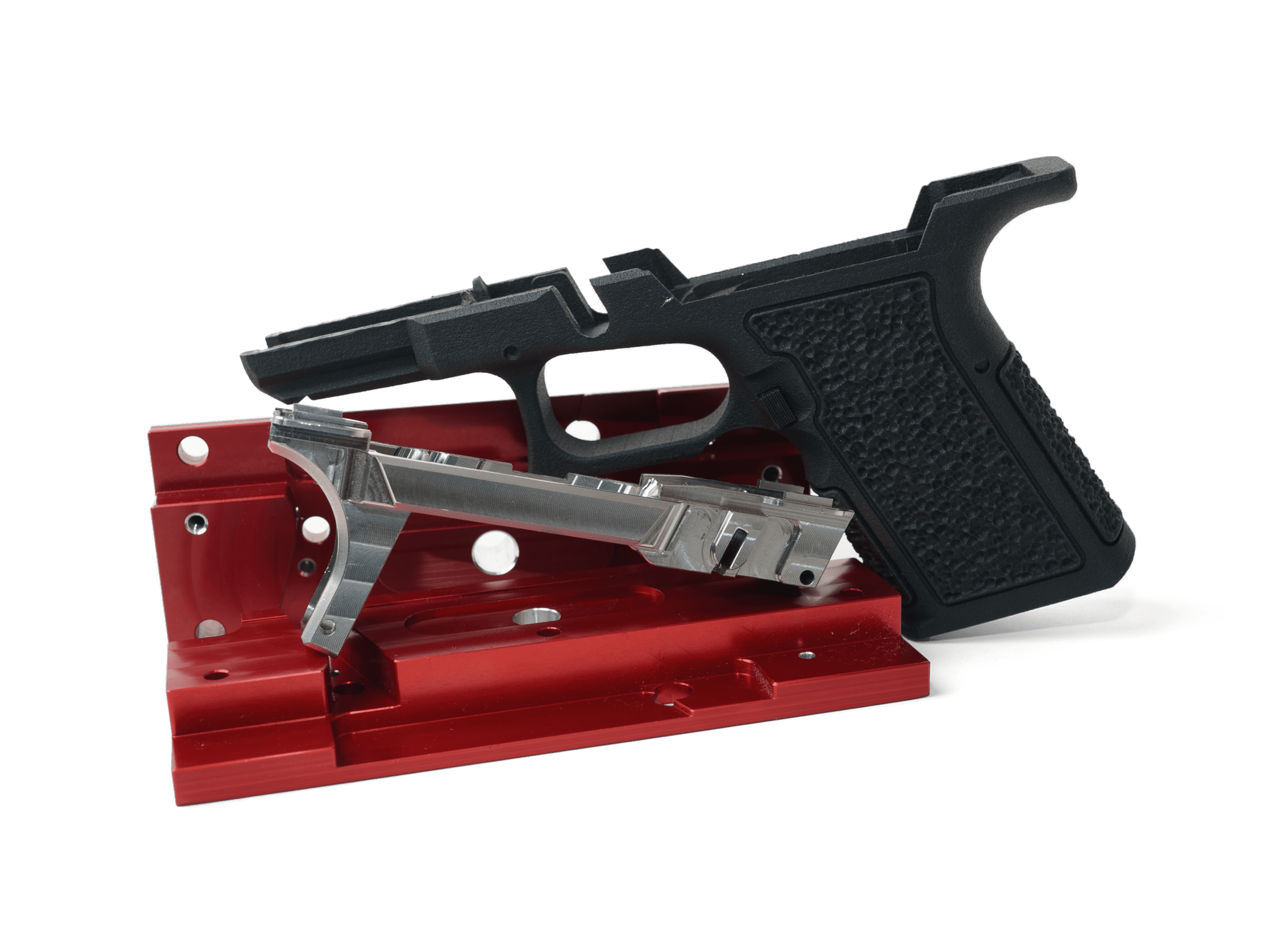

The G80 Unfinished Receiver is perfect for your next 80% pistol build.

While other 80% frames make you deal with separate components, this unfinished FCU brings everything together – the locking block, trigger housing, and slide rails are all integrated into one precision-machined unit.

If you’re after professional results from your build, you’ll love that this 80% pistol FCU works perfectly with G19 Gen3 parts. That means you’ve got access to tons of aftermarket options to make it truly yours.

The heat-treated billet steel construction gives you strength and reliability that beats 80% polymer frames every time, and the nitride finish means you won’t have to worry about corrosion – this thing is built to last.

Features

No extra parts, just clean, reliable lockup

Prevents over-insertion for smoother reloads

All-in-one assembly that stays in place

Simplifies assembly and maintenance

Improves compatibility and function

Delivers consistent, dependable ejection

In the Box

- 1x G80 Unfinished Receiver

- 2x 3mm Grip Pin

- 1x 4mm Trigger Pin

- 1x Trigger Housing Pin

- 1x Slide Lock Spring

G80 Unfinished Receiver FAQ

The G80 Unfinished Receiver is a metal fire control unit (FCU) that serves as the serialized core of your G80 build. Unlike traditional polymer 80% frames, this steel receiver combines the locking block, trigger housing, and slide rails into a single monolithic unit. Once finished, it accepts standard Glock Gen3 components to complete your privately made firearm.

The G80 Receiver is an entirely different approach to the 80% concept. While Polymer80 frames were single-piece polymer construction, the G80 uses a heat-treated 4140 steel receiver that drops into a separate grip module. This modular FCU design means you can swap grip modules without replacing the serialized component—and the steel construction offers superior durability and rigidity compared to polymer alternatives.

Yes. The G80 system was specifically designed to meet the VanDerStok compliance standard established by the Supreme Court in March 2025. The Court ruled that kits shipped without every necessary component, requiring uncommon tools and over an hour to complete, remain legal. G80 meets all three criteria, setting the new standard for federally compliant 80% firearms.

The finished G80 Receiver accepts any OEM or aftermarket Glock G19, G23, or G32 Gen3 parts. This includes complete slides, frame parts kits, and Gen3 through Gen5 magazines. Note that the G80 includes its own trigger pin, trigger housing mechanism pin, and coiled slide lock spring—these replace the corresponding parts from standard Glock lower parts kits.

No. The G80 Receiver is designed exclusively for Glock Compact-class slides—specifically the G19, G23, and G32 Gen3. Full-size (G17/G22), subcompact (G26/G27), and longslide (G34/G35) configurations are not compatible. Defense Distributed has indicated future receiver products for other platforms.

The receiver is precision CNC machined from solid 4140 steel bar stock, then heat-treated and tempered for maximum durability. The black nitride finish provides superior wear and corrosion resistance compared to standard Parkerizing or bluing—ideal for carry guns or harsh environments.

120R refers to the grip module standard developed by Defense Distributed for their G100 platform. Since the G80 Receiver shares the same chassis dimensions, it’s fully compatible with any 120R grip module. This gives you access to the entire ecosystem of G100 grip options, including open-source designs you can 3D print and customize yourself.

You’ll need a G80 Jig Set, which is available in Manual or Machine configurations. The Manual option works with a Dremel rotary tool and the included grinding stones and drill bits. The Machine option is designed for the Ghost Gunner GG3-S CNC mill. Both methods require milling metal obstructions and drilling the 3mm and 4mm pin holes.

Completion time depends on your tooling and experience. Manual finishing with a Dremel typically takes 1-2 hours for a first-time builder. Using a Ghost Gunner GG3-S with the Machine jig option significantly reduces hands-on time. The process requires more effort than polymer frames but results in a substantially more durable finished product.

Each receiver ships with the unfinished steel FCU plus the pins and springs needed for assembly: two 3mm grip pins, one 4mm trigger pin, one trigger housing pin, and one slide lock spring. These components replace certain parts from standard Glock lower parts kits.

Under current federal law, privately made firearms built for personal use do not require serialization. However, state laws vary significantly—some states require serialization of all PMFs, and others prohibit unfinished receivers entirely. The G80 is not shipped to states that have banned privately made firearms. Always verify your local regulations before purchasing.

Steel fire control units offer several advantages: tighter slide-to-frame fit, zero flex under recoil, virtually unlimited service life, and compatibility with high-round-count training regimens. The monolithic design eliminates the rail alignment issues common with multi-piece polymer frames. For builders prioritizing durability and precision over weight savings, steel is the superior choice.